Water Waste in the Fire Protection Industry: Mobilizing Solutions for a Greener Future

CHEERS TO OUR BLUE GOLD! From left to right: Manuel Blass, teacher at École Polymécanique de Laval and President of Prestige Cabinets; Stéphan Thériault, President of Consultants SynQ Inc.; Sandra D. Péloquin, Vice-President Sustainable Transformation at ACME Sprinklers Ltd.; and Mathieu Laneuville, CEO of Réseau Environnement.

In the fire protection sector, the top priority has always been — and remains — the protection of lives and property. Yet, a troubling paradox persists: the very tests and procedures designed to guarantee safety result in massive water waste. To better understand this issue and identify potential solutions, Sandra D. Péloquin, Vice-President of Sustainable Transformation at ACME Sprinklers Ltd. (ACME), met with three experts:

- Manuel Blass, teacher and trainer of backflow device inspectors, as well as fire protection mechanic entrepreneur;

- Stéphan Thériault, engineer and president of Consultants SynQ inc., a consulting firm specializing in fire protection;

- Mathieu Laneuville, Master’s graduate in water resource management and CEO of Réseau Environnement, the largest network of environmental specialists in Quebec.

How a Simple Finding Brought Key Players Together

In 2024, Sandra Péloquin commissioned Comité 21, an external sustainability consulting firm, to evaluate ACME’s carbon footprint. To her surprise, water consumption emerged as a major issue. At the plant, water use seemed minimal. However, the analysis revealed that tests required for pumps, hydrants, and sprinkler systems consumed the equivalent of several Olympic-sized swimming pools annually — over 90% of it potable water.

At first, Sandra set the matter aside, given the regulatory requirements tied to these tests. But the issue quickly resurfaced: on worksites, installers and members of ACME’s sustainable development committee voiced their unease with the waste.

“In 2025, with everything we know now, it’s more than legitimate to challenge these practices!” said André Guillemette, a seasoned ACME sprinkler installer.

This collective awakening pushed Sandra to contact the CMEICI (Corporation of Master Fire Protection System Installers of Quebec), which connected her with Stéphan Thériault. Manuel Blass and Mathieu Laneuville soon joined the discussion.

It quickly became clear: everyone acknowledged the problem, but no single player held the levers to solve it. As Stéphan explains:

“There is a real issue, and solutions exist. But as often, there are barriers: cost, time… Everyone wants to save water — until they see the bill. And above all, it will take a regulator or influential actor to truly mobilize the industry.”

Essential Tests, But Water-Intensive

Essential Tests, But Water-Intensive

Pump Tests

In most sprinkler-protected buildings, a fire pump is part of the system. Annual tests are required to ensure the pumps meet the manufacturer’s specified flow. As Manuel Blass notes:

“Right now, in the industry, everyone does the same thing: we draw potable water from the municipal system, run it through the pump… and discharge it outside. It’s a huge waste.”

A single test can consume over 60,000 gallons of water — the equivalent of six 21-foot above-ground pools. Since nearly all multi-unit residential buildings (8+ units), hotels, restaurants, schools, daycares, commercial spaces over 300 m², office towers, and warehouses are equipped with pumps, the cumulative impact is massive.

Flow Switch and Drain Tests

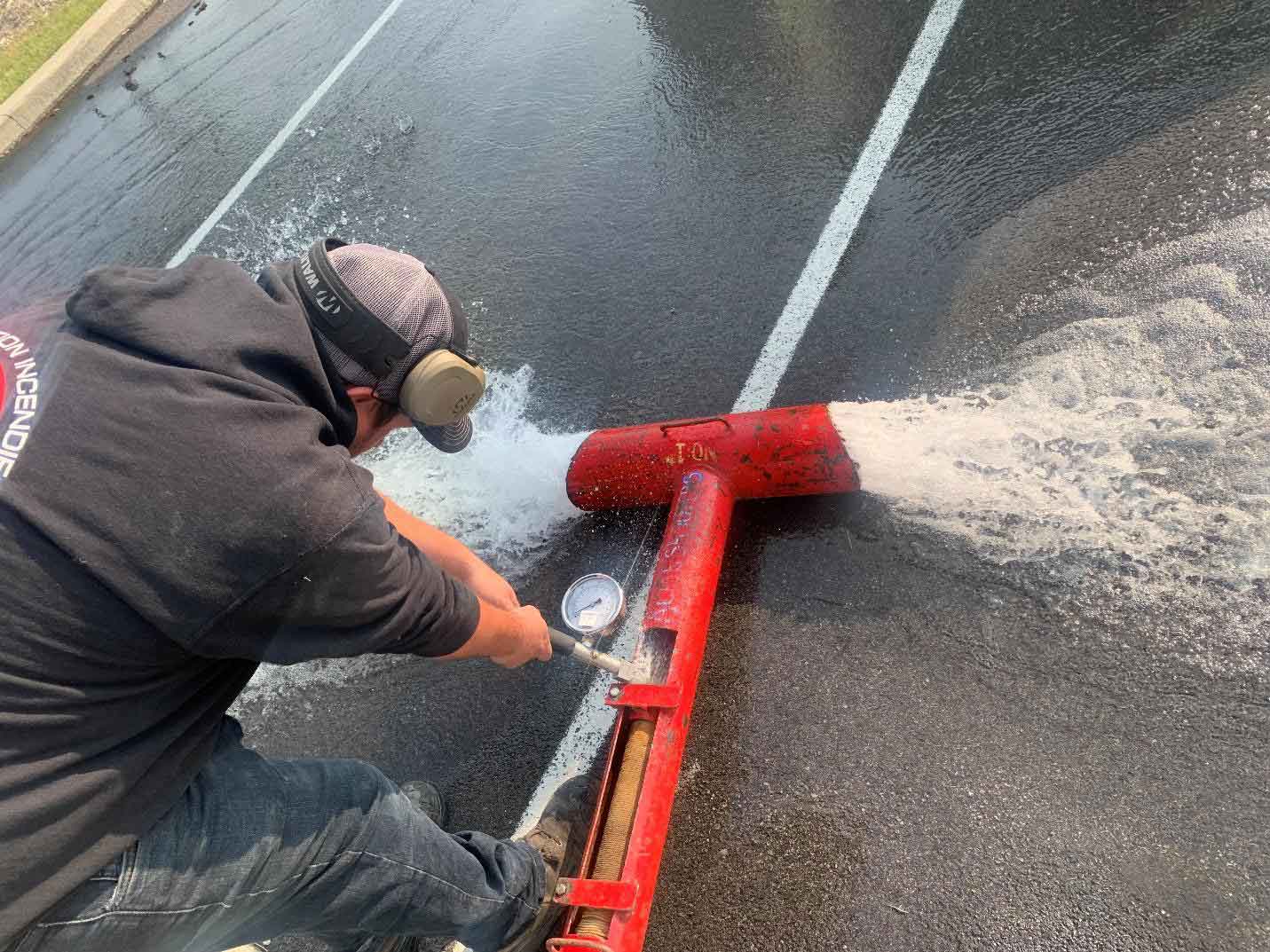

Pump tests account for only about one-third of total water use. Other tests, such as those for flow detectors (flow switches), often performed quarterly, also require running water, usually discharged through a “TEST and DRAIN” device.

Pressure Tests on New Installations

When a new system is installed, pressure tests are carried out. But, as Stéphan points out:

“Often, tests are done before construction is finished. So the system is filled, drained, refilled… several times.”

These losses are often due to scheduling constraints taking precedence over environmental considerations.

Hydrant Tests

Adequate pressure is essential for fire systems, so hydrant flow tests are conducted several times per year. Municipalities also test and flush hydrants regularly. Each test means opening the hydrant, letting water run — and losing it.

Sandra highlights an overlooked angle:

“Before a contract is even awarded, multiple companies may test the same hydrant for bidding purposes. If test results were logged in a shared register, duplication could be avoided. In Montreal, a hydrant can be tested several times in a single month.”

Solutions Already Available

- Flow Meters: Already integrated into new systems, these allow pump performance to be tested in a closed loop, with zero discharge.

- Recirculation Technologies: Alternatives for flow switch tests also exist, with the added benefit of reducing pipe corrosion by limiting oxygenated water intake.

- Training: A key step is teaching experienced technicians to use these newer technologies. Partnerships with institutions like École Polymécanique de Laval could speed the transition.

- Water Pricing: As Mathieu explains, realistic pricing — such as the $4/m³ considered by some cities — would make waste economically prohibitive. A single pump test could cost over $1,000 in potable water, encouraging behavior change.

- Cloud-Based Registries: Stéphan is developing a digital tool to centralize flow test data, reducing duplication and saving millions of liters.

- Pressure Management: As Mathieu notes, stabilizing water pressure at 60 psi in municipal systems prevents leaks and infrastructure damage while ensuring fire system reliability.

Toward a Greener Fire Protection Industry

Sandra sums it up:

“In our industry, leadership in sustainable transition is still limited. I believe this stems less from a lack of interest than from limited collective awareness and the challenges SMEs face — labor shortages, lack of in-house sustainability experts. A campaign on the environmental impact of fire safety tests could rally stakeholders and accelerate adoption of green solutions.

Could LEED certification and insurers play a key role? For instance, awarding LEED points or insurance discounts to companies adopting eco-friendly practices.

We must not take water access for granted in Quebec. Let’s lead the way, inspired by regions like California or Europe, which have already had to adapt.”

As Mathieu concludes:

“There is a perception in Quebec that water is abundant and free… but it’s only a perception.”

Conclusion: Solutions to Water Waste in Fire Protection

- Flow meters: Measure pump performance without wasting water.

- Technician training: Train all fire protection mechanics, not just newcomers, on flow meters and recirculation systems.

- Realistic water pricing: Make waste costly (e.g., $4/m³).

- Recirculation: Adopt systems to recycle water during tests instead of discharging it.

- Shared digital test registry: Avoid redundant hydrant tests and improve coordination.

- Regulatory improvements: Require flow meters for pump tests every two years (already permitted by regulation).

- Pressure management: Stabilize aqueduct pressure and use building boosters where needed.

- Collective collaboration: Bring together companies, cities, and regulators to overcome barriers and implement solutions.